Salco Global offers precision state-of-the-art 3 to 9 axis CNC Swiss Turning capabilities. We specialize in close tolerance precision sliding headstock CNC Swiss parts that meet or exceed customer's quality standards/expectations. One of our 11 specialized CNC Swiss machines is sure to meet your needs.

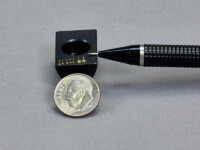

Our various Swiss turning styles allow us to pinch turn (rough & finish) simultaneously, resulting in better finishes, better tool life, and shorter cycle times. We also have Swiss turning centers capable of machining parts up to 32 inches long. Our precision micromachining is 2nd to none. We have machined parts 0.008 in diameter to 0.015 long, holding tolerances to 0.0001.

No matter how big the size of your batch, we at Salco can accommodate you - no matter if you need 250,000 components or just one individual prototype. Salco has decades of experience working with a wide range of domestic and exotic materials.

Aluminum - Brass - Beryllium Copper - Castings Aluminum / Stainless Steel - Inconel - Plastics all types - Stainless Steels all grades - Monel - MU - Titanium

We want to give you the highest quality part we can when we machine your parts at Salco, so we take the liberty of checking each part after each stage of its production. We always check each part for quality and ensure it is defect-free before moving it on to the next stage of production, ensure there are no weak links in your part's production line. A quality plan is included throughout the manufacturing process for your custom parts in conjunction with the job traveler.

Salco, Inc. provides precision CNC Swiss Machining parts and services from various industries, including electronics, automotive, medical, fiber optics, and even aerospace. We can machine the smallest of components of complex and intricate shapes from a variety of materials. We are also equally skilled with brass, stainless steel, aluminum, steel, nitronic, bronze, titanium, and plastic. We can also accommodate most component diameters up to 32MM - (1.259), and we can do that in the hardened state while holding tight tolerances of ±0.0001″.

Salco is built on quality results.

Our Denver facility is ISO 9001:2015 and AS9100D Certified, exceeding standards and medical equipment device manufacturing requirements.

We also require 1st article inspection, in-process inspection through SPC (Statistical Process Control), and final inspection throughout each operation. Parts are inspected before and after any outside processes to ensure your custom-made parts' integrity.

We offer various industry-leading quality assurance measures to help better deliver the absolute best results for each part we produce, no matter what size your project might be.

When you work with our planning and development team, you will find they can use most all file formats and are here to help guide you through the process of getting set up with your order. We are also able to meet the most strenuous turnaround times.

Companies require swiss machined parts they can depend on and a swiss machining partner they know will be there for them, help them grow, and get the job done right the first time.

At Salco, we push our team of dedicated machining experts to deliver the highest-quality machined parts possible.

We exceed expectations in parts quality, job execution, and turnaround time.

We are Salco Global – American Made Swiss Screw Machining for Manufacturers.