Salco Global offers state of the art 2- to 9-axis CNC lathe capabilities.

At Salco, we place special emphasis on precision when we lathe our products. As an extremely close-tolerance CNC machine shop, our state of the art CNC lathes and our dedication to quality mean we can produce parts of the highest quality you could ask for - quality that's almost guaranteed to meet or exceed your expectations, no matter how high they may be. As the proud owners and operators of 13 specialized CNC lathes, we guarantee that one of them is sure to have what it takes to bring your parts into reality.

While other machine shops may only produce high or low quantities exclusively, at Salco we can produce parts in any quantity. Whether it's a batch 250,000 parts, or a just one single prototype part, we've got you covered.

We have decades of experience working with all different kinds of parts, from domestic to exotic, and our decades of experience allow us to expertly work each and every one. Some of the materials we have worked with include:

Aluminum - Brass - Beryllium Copper - Castings Aluminum / Stainless Steel - Inconel - Plastics all types - Stainless Steels all grades - Monel - MU - Titanium

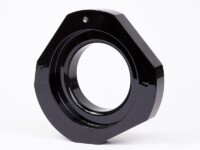

Custom CNC Lathe Turning

CNC lathing is a cornerstone in the production of hundreds of products from dozens of different industries, including telecommunications, electronics, marine, automotive, medical, and even the aerospace industry. No matter the part, it can be made from a wide variety of materials, from the famously strong stainless steel to the famously light and versatile aluminum, all with tolerances tight enough that any manufacturer would be proud to call their own.

Components machined by a CNC milling machine are also known as turned parts, these machines allow for advanced, cutting edge features and ever-more finely-crafted parts. The turning process creates turned components with dimension and depth, and is also cost-effective.

The lathing stage of a prototype's creation takes place on a CNC lathe, which turns parts at extremely fast yet highly precise speeds, making them easy for mechanical cutting devices to work with - no matter the material. CNC lathes can feature multi-spindles that can work with various workpieces together at a high production rate which allows for an even greater degree of efficiency when machining components. CNC lathes are orders of magnitude faster and more precise in its movements than any person, yet their computerized nature means they remain affordable.

At Salco, we have 13 different CNC lathing machines, each its own unique features and facets that make it excel at creating one or a few specific types of part. This specialization ultimately means better results for you and your products post-completion. CNC Lathes are great for everything from high-volume manufacturing to rapid prototyping since they can easily be set up for high repeatability.