CNC Mill

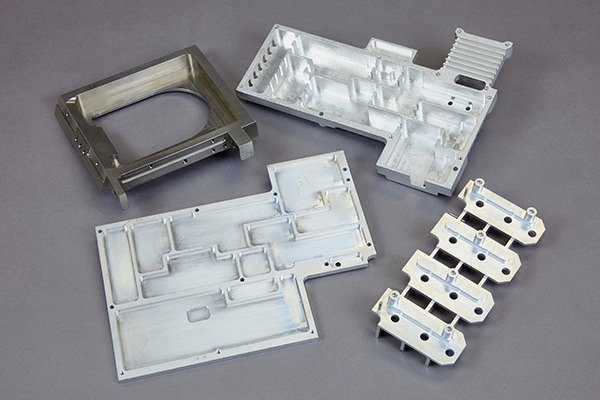

Salco Global offers precision state of the art 3 to 5 axis CNC Milling capabilities, among other CNC machining services. We specialize in close tolerance precision milled parts that meet or exceed customer’s quality standards/expectations. 1 of our 10 specialized CNC mills is sure to meet your needs.

CNC Lathe

Salco Global offers precision state of the art 2 to 9 axis CNC lathe capabilities. We specialize in close tolerance precision turned parts with live tooling and sub-spindle capabilities that meet or exceed customer’s quality standards/expectations.

CNC Swiss

Salco Global offers precision state of the art 3 to 9 axis CNC Swiss Turning capabilities. We specialize in close tolerance precision sliding headstock CNC Swiss parts that meet or exceed customer’s quality standards/expectations.

Assembly

Salco Global offers precision assembly of components whether soldered, crimped, bent, or welded. We specialize in close tolerance precision assembling of components that meet or exceed customer’s quality standards/expectations.

What Can CNC Machining Do For You?

CNC machining is capable of manufacturing extremely precise parts at a rate that has, recently, become much quicker than you might expect. Which CNC machining service is right for you and your production needs may vary — read on to discover just what each category of CNC machining services we offer at Salco can do for you.

CNC Milling

CNC milling is the most ubiquitous method for numerical control machining. With the widest capabilities of the major types of the CNC machining services, it's the most popular incarnation of the CNC process. The complexity and capacity of intricacy depends largely on the number of axes present — CNC milling machines range from 2-axis to 5-axis, with 5-axis providing the most comprehensive machining of any CNC milling method. 5-axis machines utilize both the digital X and Y axes, meaning the part at hand can be manipulated in a much wider variety of ways than a traditional 2- or 3-axis machine. Though, not all jobs require all 5 axes — simpler machines can prove more economical. At Salco, we have machines ranging from 3- to 5-axis.

CNC milling can be pivotal in manufacturing a huge variety of components for a wide variety of industries. From laser-accurate medical device components, to finely-tuned aerospace and electronic parts, CNC milling is an integral part of much of today's fine manufacturing sector.

CNC Turning (CNC Lathe)

In the CNC lathing process, the manufactured part is securely situated in a lathing machine while a computer-controlled set of ultra-fine tools machine it to precise specifications. CNC turning is primarily used to make longer, cylindrical-shaped parts as a more traditional lathe would. Similarly to CNC milling, CNC turning varies in complexity and capability depending on the number of axes present. At Salco, we're capable of providing every axis from 2- to 9-axis.

CNC turning is a popular choice for auto parts, gun barrels, precision piping, and even recreational wooden instruments like pool cues and high-grade baseball bats.

CNC Swiss Turning

CNC Swiss operates in a somewhat similar capacity to the aforementioned CNC lathing, but instead of the tools spinning rapidly around the part, the part itself spins rapidly. This makes CNC Swiss turning much better suited for smaller, finer parts than traditional CNC lathing. At Salco, our Swiss capabilities are just as wide as our lathing and milling capabilities, with machines on offer ranging from 3- to 9-axis.

For many highly-technical and advanced industries, like aerospace, medicine, defense and more, CNC Swiss turning provides extremely precisely-made screws, nails, shafts and other crucial support elements at a very fast rate.

Component Assembly

After your parts are machined and ready for use, we here at Salco also offer in-house assembly of your completed components. Whether your parts need to be soldered, crimped, bent or welded, Salco is your one-stop-shop for prototyping and design-to-completion services.