HISTORY OF SWISS MACHINING

The first-ever Swiss Screw machine was developed in Switzerland back in the 19th century. This machine quickly made its mark as the premier lathe for the production of small and complex parts.

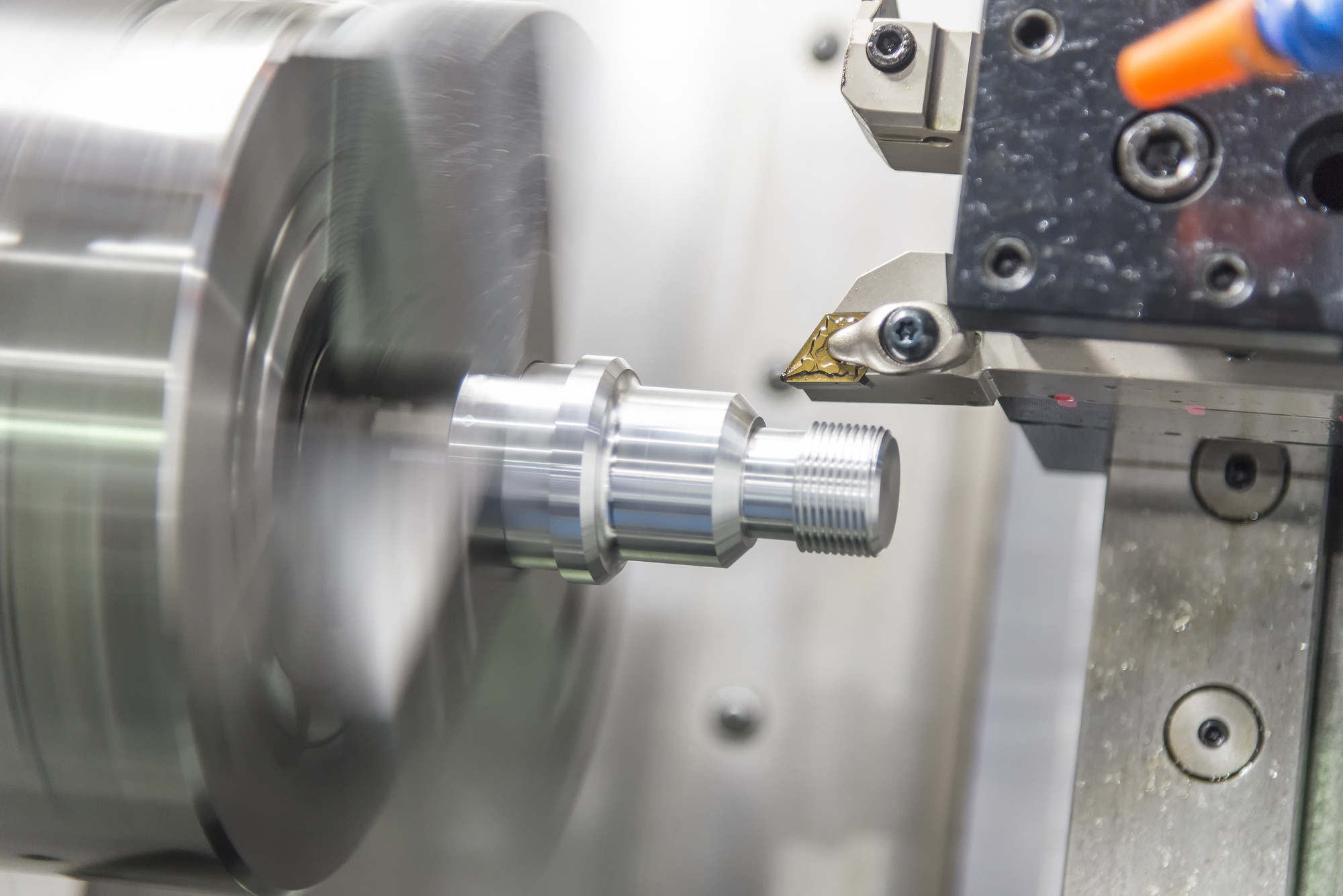

CNC swiss screw machines differ quite a bit from conventional lathes, as CNC swiss machining moves the bar stock through a bushing using a sliding headstock. The headstock moves the material forward and backward, exposing only the portion of the material being machined.

When it comes to utilizing the gang tool and guide bushing, it provides close proximity to the cutting device to the material being cut, minimizing deflection and delivering an increased precision while holding tight tolerances. As with other machining processes like lathes and mills, the Swiss CAM automatic machine has led CNC Swiss machines to better-streamlined automation.

WHAT ARE THE ADVANTAGES OF A CNC SWISS MACHINE SHOP?

PRODUCTIVITY

Currently, the Swiss Screw machines in use will rely on a computer numerical control (CNC) unit to process the parts designed to meet specifications by following a coded, programmed instruction without a manual operator.

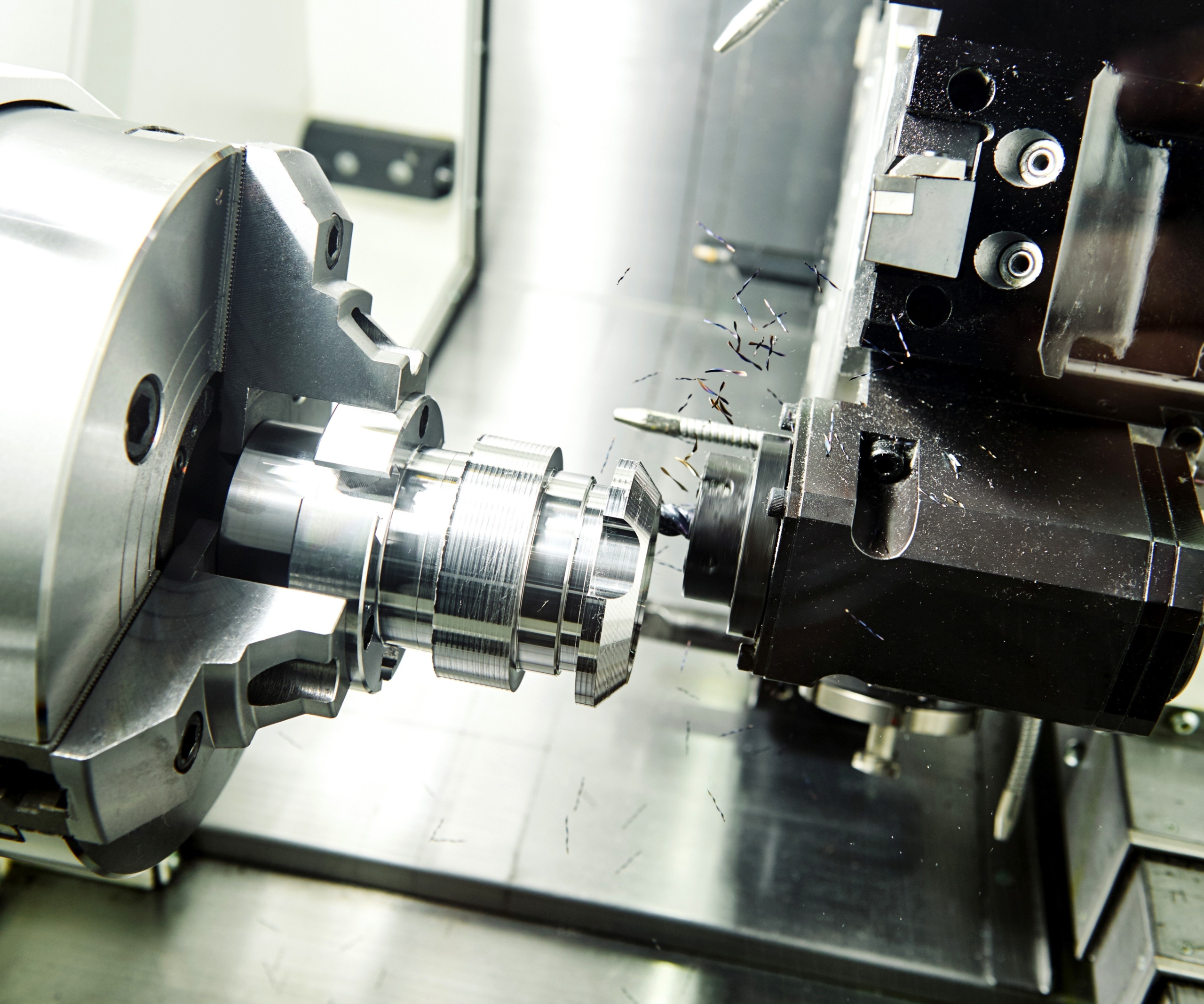

With room for over 20 different tools and the ability to perform multiple operations concurrently, complex parts can now be completed in one operation on the machine as opposed to multiple operations that traditional lathes requiring.

CNC Swiss machine shops also offer the capabilities for a secondary process such as milling, slotting, cross-tapping, and cross-drilling, and eliminating the need for any additional machining once the parts that are turned come off the machine.

HIGHER VERSATILITY

CNC swiss machining usually works in diameters under 1 ¼” and, with the majority of work that is performed is smaller than ¾”, but they also excel at producing tons of different parts with lengths greater than the diameter. The ability to make slender, more extended parts while reducing deflection is a huge benefit to running those larger length-to-diameter parts on a Swiss machine.

LARGER COST SAVINGS

The new Swiss machines required smaller work-pieces, which allows you to use a smaller bar stock. The lower cost of these materials turns into lower overall production costs, all without sacrificing any product quality.

The Swiss machines can now achieve greater accuracy and precision, even in complex and intricate designs. With a good bar stock quality, the swiss machine will allow for tight tolerance, often eliminating the need for any outside grinding service. Additionally, once your machine has been set up and provisioned, you will notice that some parts will allow for an unmanned runtime; this will increase your labor efficiency in the shop while cutting down lead times for your customers.

APPLICATIONS OF SWISS MACHINES

The machines were originally created a long time ago to manufacture screws for the watchmakers and their industry; over time, machines have evolved across multiple industries. While these machines still create parts for high-end watchmakers, they also can be found making screws for a range of applications, including:

The machines were originally created a long time ago to manufacture screws for the watchmakers and their industry; over time, machines have evolved across multiple industries. While these machines still create parts for high-end watchmakers, they also can be found making screws for a range of applications, including:

- Medical components

- Industrial components

- Aerospace and defense industries

- Components for musical instruments

With the ability to machine many different types of metals with tight dimensional tolerances, there is next to nothing that the Swiss machines cannot do when it comes to machining parts.

WHAT MATERIALS DO WE USE IN SWISS MACHINING?

a swiss machine shop like Salco can employ a variety of materials depending on the specifications required from the components. These range from common materials like exotic alloys:

- Aluminum

- Brass

- Bronze

- Carbon Steel

- Copper

- Plastics

- Stainless Steel

- Steel

- Tool Steel

- Titanium

- Exotic Alloys

TYPES OF SWISS SCREW MACHINES

There are a few types of swiss machines on the market today.

There are a few types of swiss machines on the market today.

Swiss- and Turret-Style Machines

The Turret-type screw machine produces very similar results to the Swiss-style machines. One advantage of the new CNC Swiss screw machine is that many more tooling fixtures can now be applied, and, despite screw machines typically being “single spindle,” the possibility is also thereof using it as a double spindle machine. This time-saving feature effectively cuts out the operator.

This part is automatically transferred from the screw machine to another machine for the secondary operation saving in labor cost for which an operator would generally have to be there to complete. Turret-style screw machines also come equipped with a transfer attachment that can also perform this function as well.

The Turret type, also known as Brown & Sharpe, named after its first manufacturer, mounts the work-piece on a vertical ram, which works into the lathe. The Swiss-type was originally named after its place of origin where swiss watchmakers used it for precision components, mounts the work-piece on a rotary slide. While these two types function differently, their benefits and output are essentially the same, although the Swiss screw machine is better at more precise work.

CNC Swiss Machine – Applications

The other is Computer Numerically Controlled (CNC) machines, and these use a CNC unit to control all of the tools, which allows parts to be made to exact specifications.

Benefits of the CNC Swiss Machine

When it comes to the CNC machines, they offer a level of control that may not be possible with a standard automatic Swiss screw machine. Our CNC swiss machines allow the use of tools on multiple axes, allowing more tooling for both milling and turning. Cycle times of the machines are reduced, and more detailed parts can be created with the use of the abilities provided by the CNC machines saving our clients money in the long run.

Operations can be performed in a shorter period in CNC Swiss machining. This screw machine can rotate parts at up to 10,000 RPM with an accuracy level ranging between 0.0002 to 0.0005 inches. In addition to being extremely precise, the CNC Swiss machine also reduces waste and gives more flexibility when machining a specific part.

Swiss machining is a viable manufacturing process for many industrial application needs. Compared to traditional turning processes, it offers greater precision, versatility, productivity, and cost-effectiveness.

CNC screw machines are automated machines that are used to machine turned parts. The appellation “screw machine” might be misleading, as they don’t screw anything in, nor do they thread materials, although this is one of their functions. Basically, the machine components by spinning on a very quickly rotating lathe, which shaves the metal down to the desired size.

With over two decades of experience, we have the knowledge, skills, and tools to fulfill any CNC Swiss precision turning need. To learn more about our services and capabilities, contact us today for pricing details.

If you are looking for a partner for your next Swiss machining project, turn to the experts at Salco Global.