We are often asked why working with us is worth it — what makes us different from other companies? Thanks to our consistent development, and always keeping our customers’ needs at the forefront of our minds, we have been able to constantly expand our capabilities. From prototyping to large CNC milling jobs, delivering high quality to our customers is paramount. In this article, we will show you why Salco Global is the best choice for you.

We Have Top Industry Accreditation

We have obtained the ISO 9001:2015 certification, which is a globally accepted standard that outlines the criteria for an outstanding quality management system (QMS). The standard is used by businesses to show that they can consistently deliver products and services that fulfill consumer and regulatory criteria.

Our company is a certified AS9100D CNC machine shop. The Society of Automotive Engineers (SAE) produced a standard named “Quality Management Systems – Requirements for Aviation, Space, and Defense Organizations,” and this is what the AS9100D is based on.

Manufacturers, contractors, and suppliers who conduct business in the aerospace sector are eligible for this accreditation. The regulations place a large emphasis on preventing danger and the use of counterfeit components, as well as establishing a framework that allows organizations to adapt to change, prepare for obsolescence, and address product safety problems.

A Lights-Out Production Environment

Our customers may enjoy a lights-out production environment. We offer solutions that allow design and post-prototyping processes to be fully automated, eliminating the need for human intervention, ensuring that ordered components and parts are always of the highest quality.

The “lights-out” environment gets its name from the fact that the automation can run outside of normal business hours, even as long as 24 hours per day. Using fewer people means greater cost efficiency, which ultimately means we can provide you with considerably lower rates.

We Maintain Tolerances as Low as +/- .0001

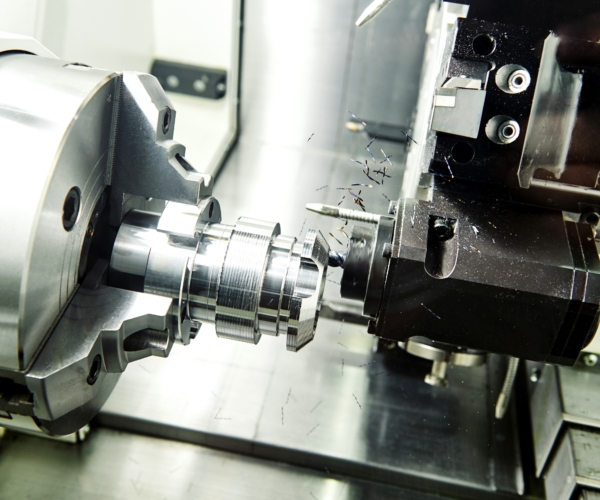

Salco Global has state of the art CNC Swiss Turning capabilities, which range from three to nine axes. We specialize in precision sliding headstock CNC Swiss components with ultra-low tolerances that meet or exceed our clients’ quality expectations.

Because of our Swiss turning methods, we can pinch turn (rough and finish) at the same time, resulting in superior finishes, longer tool life, and lower cycle times. We also offer Swiss turning centers that can machine pieces as long as 32 inches. Our precision micromachining is unrivaled in the industry.

We’ve machined items ranging in size from 0.008 in diameter to 0.015 in length, with 0.0001 tolerances. This high level of precision allows us to produce our parts with even greater precision than the aerospace industry calls for.

Fast Turnaround Times Even With an Extremely High Volume

Thanks to our lights-out environment, we are available up to 24 hours a day, every day of the year. In addition, thanks to our extensive CNC machine shop and turning machine park, we can deliver quantities of up to 250,000 components on short notice.

Over Three Decades of Experience in the Industry

We founded Salco Global in 1985 with the goal of developing the lowest-tolerance machines in the business. Our CNC machine shop prioritizes staff training and retention, so our years of expertise show in our speed, precision, clear communication, and can-do attitude.

Contact our customer success team if you want the best CNC machine shop services available — we would be happy to assist you!