The days of tedious, one-by-one mechanized CNC production are rapidly ending. As technology progresses faster and faster, the methods of machining you may be used to are quickly becoming obsolete in the face of other, more advanced methods. If you’re sticking to what’s worked in the past, we wouldn’t blame you – but if your’s is a business that relies heavily on mechanized production, or you’re a serial prototyper, we think you’ll enjoy the benefits of a modern, more advanced production pipeline.

At the top of the list of new innovations brought on by recent innovation, is automation. In this article, we’ll go over a few key reasons why automated CNC production is the way forward in high-precision CNC machine shops, and how our automation capabilities at Salco Global are already ahead of the curve.

Scalability

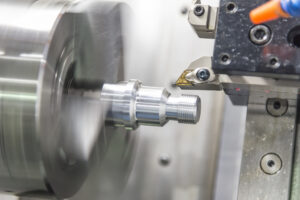

In the early days of CNC machining, machines had to essentially be babysat to ensure proper function, and so that machined parts could be manually assembled and/or swapped out for fresh, unworked materials once the machining finished. While still an innovation in itself at the time, by today’s standards it was slow, inefficient, and an all-around inferior process.

In the early days of CNC machining, machines had to essentially be babysat to ensure proper function, and so that machined parts could be manually assembled and/or swapped out for fresh, unworked materials once the machining finished. While still an innovation in itself at the time, by today’s standards it was slow, inefficient, and an all-around inferior process.

This resulted in lackluster scalability. The cost per unit machined rose substantially when the volume grew, as more and more people needed to attend to the machines and calibrate others.

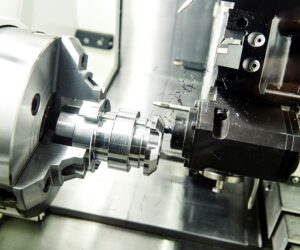

With automated CNC production, these inefficiencies have become a thing of the past. CNC machines can automatically machine one in-progress component, then acquire another pre-worked component and do the same – no need for a person to swap out the component manually. Removing the need for constant human intervention, the scalability of CNC machining increases dramatically, resulting in a greatly reduced price per part at scale, not to mention the likewise increased efficiency of the CNC process.

Speed

With the increase in efficiency, it’s natural that an increase in speed will coincide. With production speed having triple the amount of time in a day to occur, think 24 hours vs. 8 hours, your CNC production will have never been faster.

Gone are the days when CNC production had to be limited by the number of hours in a work day. With our fully-automated process that runs through all hours of the day, you can enjoy all the fruits of the CNC industry’s innovation at a fair rate.

Price

So far, we’ve discussed one key factor about automation more than the rest — the new ability to work without human intervention — and there’s good reason for that. With a fully automated CNC production line, not only do you receive your components faster than ever before, but you’ll get them cheaper than ever before as well. With far fewer man hours per part machined, we eliminate the costs that those hours would entail.

By taking those costs off, we can in essence deduct those costs from your bottom line. In non-automated machine shops, those excess man hours would be loaded off on to you, the client, meaning you’d be paying for more labor than is truly necessary. In an automated shop, less labor on our ends means more affordable components for you.