The automotive industry, a long-standing pillar of global manufacturing, has continually evolved over the past century. The pivotal force behind this relentless transformation is the continual introduction and integration of advanced technologies. At the heart of this revolution lies Computer Numerical Control (CNC) production. This modern manufacturing approach has redefined the boundaries of precision, quality, and efficiency within this particular sector.

CNC machining is a process that uses pre-programmed software to control the movement of factory machinery and tools. This technology, vital in automotive manufacturing, ensures absolute precision and repeatability, making it ideal for producing the complex parts automobiles require. This article delves into the influence and benefits of CNC production in automotive manufacturing.

Elevated Precision and Consistency

The automotive industry demands exceptional precision. Parts such as engine blocks, suspension components, and transmission systems, amongst others, require exact dimensions for optimum performance. CNC machines meet this need for precision with ease. With the ability to work within tolerances as tight as 0.001 inches, CNC production in automotive manufacturing guarantees high-level accuracy consistently across large production runs.

Enhancing Productivity

CNC machining boosts productivity in automotive manufacturing. The machines can operate continuously, 24/7, requiring only occasional maintenance. Moreover, they can seamlessly execute complex sequences that would be incredibly challenging and time-consuming for manual operators. This automation increases output, reduces lead times, and enhances overall efficiency within the automotive industry.

Versatility and Flexibility

CNC production in automotive manufacturing enables the manufacture of a wide variety of parts from different materials, including steel, aluminum, brass, and numerous plastics. This versatility is coupled with remarkable flexibility. With CNC machines, transitioning between different production applications involves simple software modifications, making it easier to adapt to design changes or varying customer requirements.

Minimizing Waste

In the automotive manufacturing industry, material waste equals financial loss. CNC production minimizes waste by optimizing material usage. The machines’ precision reduces the chance of errors, lowering scrap rates. Furthermore, CNC production is digital, allowing manufacturers to simulate the production process before actual machining. This capability enables them to identify potential problems and resolve them before they affect material usage.

Increasing Safety

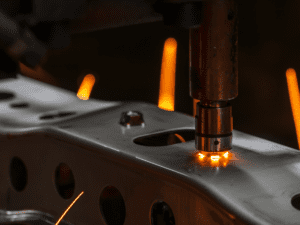

Safety is paramount in any manufacturing setting. CNC machines reduce the risk of workplace accidents by performing the most dangerous tasks. The CNC machining process is largely automated, reducing human interaction with the sharp tools that can lead to injuries.

Concerns of CNC Production in Automotive Manufacturing

While the benefits of CNC production in automotive manufacturing are numerous, it is essential to also address potential concerns. A primary issue is the significant initial investment required for CNC machines. They are more expensive than their manual counterparts, which may deter smaller manufacturers. However, the long-term return on investment is substantial, given the reductions in labor costs, material waste, and production time.

Another concern is the technical skill set required to operate and maintain these machines. As automation increases, there’s a need for employees to have a higher level of computer and engineering expertise. This could potentially lead to job displacement for workers with traditional manufacturing skills. Lastly, the complexity of CNC systems may raise worries about maintenance and repair costs. Despite these concerns, the consensus within the industry is that the advantages of CNC production far outweigh the challenges, given its potential to revolutionize automotive manufacturing.

Cost-Effective Mass Production

For the automotive industry, where mass production is the norm, CNC production is a godsend. The high initial cost of CNC machinery is quickly offset by benefits like reduced labor costs, faster production times, and decreased waste.

In conclusion, CNC production in automotive manufacturing has fundamentally altered the landscape of the process. It offers unprecedented levels of precision, consistency, versatility, and safety, while enhancing productivity and cost-effectiveness. As we venture further into the era of electric and autonomous vehicles, the role of CNC production in automotive manufacturing will only increase, underscoring its pivotal role in driving the industry forward.