Who are we at

Salco Global?

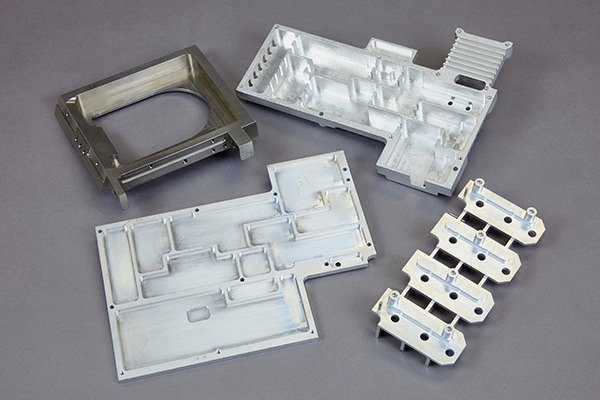

Salco Global is a precision machine shop established in 1985 with over 3 decades of experience manufacturing precision close tolerance machined components and assemblies. We work closely with a wide range of industries worldwide.

Our customer base includes industries such as:

- Aerospace

- Automotive

- Communications

- Computers

- Medical Devices

- Spray Finish Technologies

- New to Market Industries

The Salco Global Precision Machining team welcomes new business opportunities. If your company is looking for a quality CNC machine shop that can handle difficult projects on-time, and with maximum precision, we want to work with you!

Our Services

CNC Mill

Salco Global offers precision state of the art 3 to 5 axis CNC Milling capabilities. We specialize in close tolerance precision milled parts that meet or exceed customer’s quality standards/expectations. 1 of our 10 specialized CNC mills is sure to meet your needs.

CNC LATHE

Salco Global offers precision state of the art 2 to 9 axis CNC lathe capabilities. We specialize in close tolerance precision turned parts with live tooling and sub-spindle capabilities that meet or exceed customer’s quality standards/ expectations.

CNC Swiss

Salco Global offers precision state of the art 3 to 9 axis CNC Swiss Turning capabilities. We specialize in close tolerance precision sliding headstock CNC Swiss parts that meet or exceed customer’s quality standards/expectations.

Assembly

Salco Global offers precision assembly of components whether soldered, crimped, bent, or welded. We specialize in close tolerance precision assemblingof components that meet or exceed customer’s quality standards/ expectations.